FACILITY LAYOUT OPTIMIZATION SOFTWARE

Unbeaten Performance.

Unmatched Functionality.

Fully Automated Optimization.

Now, online web app:

Full Refund Guarantee:

A full refund is guaranteed if any other software can produce better layouts for your facility layout problem.

MOTIVATION

Layout Optimization is one of the top issues for industrial facility planners in USA and around the world. It has profound effects on organizational productivity and profitability. Optimized layouts reduce material handling cost, streamline the activities, and reduce energy bills. With about a trillion dollars being spent on new facilities each year in USA alone, it is natural that industrial facility planners like to have a superior “Facility Layout Optimization” software.

VIP-PLANOPT fills this gap for the facility planners. It has a robust hybrid proprietary optimization algorithm. The advent of this pioneering package more than 30 years ago, accompanied with a candid and uncontested claim: No other software produces better (lower-cost) layouts for any known set of benchmark problems. Since then, it has maintained this claim.

DISTINCT FEATURES

VIP-PLANOPT is a practical and efficient tool for industrial facility layout designers. It can solve large problems of up to 1000 departments with a speed no other optimization algorithm can match and with guaranteed lowest cost layouts.

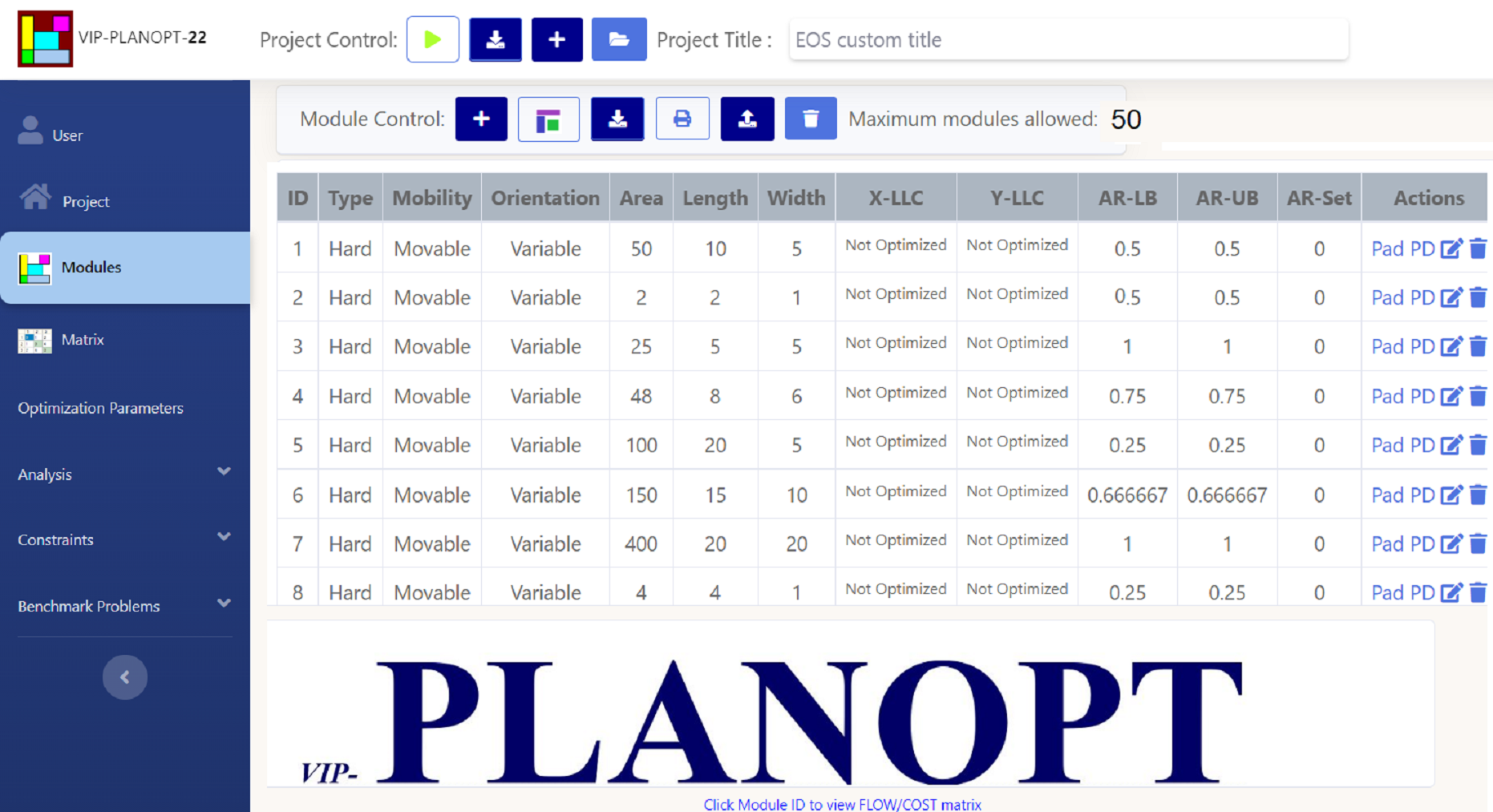

Easy Data Entry

VIP-PLANOPT minimizes the modeling and data input time. Most of the input requires just

a few clicks of the mouse.

Minimum User Interaction

No initial design or user-specified tuning parameters are required. Produces optimized layouts without any user interaction.

Optimum Orientation

VIP-PLANOPT can determine the optimum orientation of departments that have

user-specified fixed dimension.

Pick-up and Drop-off

Points

The user can specify pick-up and drop-off points anywhere inside or outside the boundary of a department with a click of the mouse pointer.

Anchored Module

Departments tagged as Anchored by the user are kept

precisely at the user-specified locations in the optimal layouts.

Composite Boundary

The user can specify a rectangular or composite boundary. If feasible, VIP-PLANOPT will produce optimized layout within the specified boundary.

Composite cost

function

Composite cost function option allows the user to specify a weight on the area of the

rectangle enclosing all the modules in the optimized layout.

Module Padding

The user can specify padding of empty space around the modules.

Optimized layouts will have modules seperated by the specified padding.

Compare

Alternative Layouts

Graphical display of the optimized layout allows the user to relocate any departments

and compare the cost of alternative layouts.

Forbidden Area Module

(FAM)

VIP-PLANOPT has introduced a novel concept of Forbidden Area Module to model

obstructions and non-usable spaces of a facility.

Inter-department Distance

The user can specify upper bounds on distances between any pair

of departments. This keeps the two departments within a given distance in the optimized layout.

Negative Flow

The user can specify negative flow between any pair of departments.

This keeps the two departments as apart as possible in the optimized layout.

VIP-PLANOPT ALGORITHM

VIP-PLANOPT is based on a proprietary hybrid heuristic-cum-analytical technique which has evolved through years of research work. It can generate high quality solutions for large scale problems with minimal computational cost. This is due to PLANOPT’s underlying search philosophy of identifying, for each block, the feasible design space with the highest probability of the optima. A pseudo- exhaustive search is then carried out for the optimum solution at each stage of a multi-stage optimization process. VIP-PLANOPT improves its optimization algorithm with double precision arithmetic which makes the software more stable and almost crash-proof.

TESTIMONIALS

Textbooks referring to VIP-PLANOPT

|

Facilities planning |

Tompkins, James A., et al. Facilities planning. John Wiley & Sons, 2010. |

|

Facilities design |

Heragu, Sunderesh S. Facilities design. Crc Press, 2018. |

|

Location and Layout Design in Plant Using VIP-PLANOPT Software |

|

|

Multi-objective evaluation of dynamic facility layout using ant colony optimization |

Chen, Gary Yu-Hsin. Multi-objective evaluation of dynamic facility layout using ant colony optimization. The University of Texas at Arlington, 2007. |

|

Operations and Production Systems with Multiple Objectives |

Malakooti, Behnam. Operations and Production Systems with Multiple Objectives. United Kingdom, Wiley, 2014. |

|

The Routledge Companion to Production and Operations Management |

The Routledge Companion to Production and Operations Management. United Kingdom, Taylor & Francis, 2017. |

|

Job Shop Lean An Industrial Engineering Approach to Implementing Lean in High-Mix Low-Volume Production Systems |

Irani, Shahrukh A.. Job Shop Lean: An Industrial Engineering Approach to Implementing Lean in High-Mix Low-Volume Production Systems. United States, Taylor & Francis, 2020. |

Scholarly articles referring to VIP-PLANOPT

|

Title |

Citation |

|

Adjacency-Based Facility Layout Optimization for Shipyards: A Case Study |

Tamer, Salim, et al. "Adjacency-Based Facility Layout Optimization for Shipyards: A Case Study." Journal of Ship Production and Design 39.01 (2023): 25-31. |

|

A Mathematical Model for Determining the Facility Layout Plan of a Plastic Injection Factory |

Kaklıkkaya, Harun, et al. "A Mathematical Model for Determining the Facility Layout Plan of a Plastic Injection Factory." Enthusiastic: International Journal of Applied Statistics and Data Science (2023): 212-221. |

|

A Unique Strategy for Improving Facility Layout: An Introduction of The Origin Algorithm |

Nordin, Nurul Nadia, Ruzanna Ab Razak, and Govindan Marthandan. "A Unique Strategy for Improving Facility Layout: An Introduction of The Origin Algorithm." Sustainability 15.14 (2023): 11022. |

|

Optimization of Material Flow of Woodshop Through Layout Redesign |

Wegner, Madison. "Optimization of Material Flow of Woodshop Through Layout Redesign." (2023). |

|

Shipyard facility layout optimization through the implementation of a sequential structure of algorithms |

Junior, W. Azzolini, et al. "Shipyard facility layout optimization through the implementation of a sequential structure of algorithms." Heliyon (2023). |

|

Osnivanje mješovitog brodogradilišta visoke tehnološke razine |

Safić, Edvin. Osnivanje mješovitog brodogradilišta visoke tehnološke razine. Diss. University of Rijeka. Faculty of Engineering. Department of Naval Architecture and Ocean Engineering. Section of Technology and Organisation of Ship Building, 2023. |

|

A comprehensive investigation into the performance of genetic algorithm for effective shipyard topological layout |

Türk, Abdullah, et al. "A comprehensive investigation into the performance of genetic algorithm for effective shipyard topological layout." Proceedings of the Institution of Mechanical Engineers, Part M: Journal of Engineering for the Maritime Environment 236.3 (2022): 726-740. |

|

An Optimal Layout Pattern-Based Solution Approach to the Extended Machine Layout Problem With Multirow Multicolumn Structure |

Qi, Mingyao, Xinru Hao, and Meng Yuan. "An Optimal Layout Pattern-Based Solution Approach to the Extended Machine Layout Problem With Multirow Multicolumn Structure." IEEE Transactions on Automation Science and Engineering 20.2 (2022): 1408-1428. |

|

A survey on discrete space and continuous space facility layout problems |

Hunagund, Irappa Basappa, V. Madhusudanan Pillai, and Kempaiah UN. "A survey on discrete space and continuous space facility layout problems." Journal of Facilities Management 20.2 (2022): 235. |

|

An Application of an Unequal-Area Facilities Layout Problem with Fixed-Shape Facilities |

McKendall, Alan, and Artak Hakobyan. "An Application of an Unequal-Area Facilities Layout Problem with Fixed-Shape Facilities." Algorithms 14.11 (2021): 306. |

|

Facility layout planning. An extended literature review |

Pérez-Gosende, Pablo, Josefa Mula, and Manuel Díaz-Madroñero. "Facility layout planning. An extended literature review." International Journal of Production Research 59.12 (2021): 3777-3816. |

|

PROBLEMS FOR EQUAL AND UNEQUAL FACILITY LAYOUT USING THE ORIGIN HEURISTIC |

Nordin, Nurul Nadia, Govindan Marthandan, and Ramakrishnan Kannan. "PROBLEMS FOR EQUAL AND UNEQUAL FACILITY LAYOUT USING THE ORIGIN HEURISTIC." Proceedings of The 2 nd Conference on Managing Digital Industry, Technology and Entrepreneurship (CoMDITE 2021). |

|

Perancangan Ulang Tata Letak Fasilitas di CV. Sahara Putra untuk Menurunkan Jarak dan Momen Perpindahan Material |

KHARISMA, Andhika Akbar. Perancangan Ulang Tata Letak Fasilitas di CV. Sahara Putra untuk Menurunkan Jarak dan Momen Perpindahan Material. Diss. Universitas Jenderal Soedirman, 2021. |

|

A case study on productivity improvement in a display cases manufacturing industry |

Jayachitra, R., and S. Parthasarathy. "A case study on productivity improvement in a display cases manufacturing industry." International Journal of Productivity and Quality Management 31.2 (2020): 151-166. |

|

ÇELİK KAPI SEKTÖRÜNDE TESİS YERLEŞİM PROBLEMİ: BİR UYGULAMA |

Koçak, Nurettin, and Adem TÜZEMEN. "ÇELİK KAPI SEKTÖRÜNDE TESİS YERLEŞİM PROBLEMİ: BİR UYGULAMA." Journal of Business in The Digital Age 3.2 (2020): 129-135. |

|

An Integrated Approach Based On A Bi-Level Genetic Algorithm And A Combined Zonelp For The Facility Layout Problem |

Mohamadi, Arash, et al. "An Integrated Approach Based On A Bi-Level Genetic Algorithm And A Combined Zonelp For The Facility Layout Problem." South African Journal of Industrial Engineering 30.4 (2019): 87-101. |

|

A new two-stage approach for a bi-objective facility layout problem considering input/output points under fuzzy environment |

Mohamadi, Arash, et al. "A new two-stage approach for a bi-objective facility layout problem considering input/output points under fuzzy environment." IEEE Access 7 (2019): 134083-134103. |

|

Advanced scientific algorithms in digital factory design applications |

Lohmer, Jacob, Armin Klausnitzer, and Rainer Lasch. "Advanced scientific algorithms in digital factory design applications." The Road to a Digitalized Supply Chain Management: Smart and Digital Solutions for Supply Chain Management. Proceedings of the Hamburg International Conference of Logistics (HICL), Vol. 25. Berlin: epubli GmbH, 2018. |

|

Compressed Air Systems Evaluation and Improvement |

Swoboda, Lukas. "Compressed Air Systems Evaluation and Improvement." (2018). |

|

Perencanaan Tata Letak Pabrik Rekomendasi Perbaikan Pada PT. X |

Wijaya, Kurnia, Muhammad Dzaki Adani, and Rizky Isa Divianto. "Perencanaan Tata Letak Pabrik Rekomendasi Perbaikan Pada PT. X." Prosiding Seminar Sains Nasional dan Teknologi. Vol. 1. No. 1. 2018. |

|

Rancangan sistem informasi manajemen persediaan Toko Sepatu Paris |

Hadinata, Chandra. "Rancangan sistem informasi manajemen persediaan Toko Sepatu Paris." (2018). |

|

An integrated fuzzy algorithm approach to factory floor design incorporating environmental quality and health impact |

Azadeh, Ali, et al. "An integrated fuzzy algorithm approach to factory floor design incorporating environmental quality and health impact." International Journal of System Assurance Engineering and Management 8 (2017): 2071-2082. |

|

A hybrid genetic algorithm with decomposition phases for the unequal area facility layout problem |

Paes, Frederico Galaxe, Artur Alves Pessoa, and Thibaut Vidal. "A hybrid genetic algorithm with decomposition phases for the unequal area facility layout problem." European Journal of Operational Research 256.3 (2017): 742-756. |

|

Parametric design |

Asanowicz, Aleksander. "Parametric design." SharingofComputableKnowledge! (2017): 379. |

|

Studi Kasus Perbandingan Perancangan Tata Letak Fasilitas Pabrik Pada Pt Sennatra Pendawatama Secara Manual Dan Dengan Software Vip-Planopt10 |

Hartono, Natalia, And Yuliana Yuliana. "Studi Kasus Perbandingan Perancangan Tata Letak Fasilitas Pabrik Pada Pt Sennatra Pendawatama Secara Manual Dan Dengan Software Vip-Planopt10." Journal Industrial Servicess 3.1c (2017). |

|

Propuesta de mejora del flujo de material para la empresa Creaciones Medellín Ltda |

Briceño Bermúdez, Briggith Alejandra. "Propuesta de mejora del flujo de material para la empresa Creaciones Medellín Ltda." (2017). |

|

Lean Implementation through Enhancing Productivity in a Pump Industry |

Aravinth Kumar, A., and D. Rajenthirakumar. "Lean implementation through enhancing productivity in a pump industry." International Journal of Engineering Research 5.5 (2016): 429-432. |

|

Identification of promising infant clusters to obtain improved block layout designs |

Mir, Mustahsan, Ahmed Hassanin, and Mohammed A. Al-Saleh. "Identification of promising infant clusters to obtain improved block layout designs." International Journal of Industrial and Manufacturing Engineering 10.3 (2016): 488-493. |

|

Implementation of Lean in Automotive Component Manufacturing Process |

Scholar, P. G. "Implementation of Lean in Automotive Component Manufacturing Process." (2016). |

|

Kriteriji za določitev optimalne razporeditve delovnih sredstev na primeru proizvodnega obrata Mizarstvo Jezeršek doo |

Jezeršek, Marjeta. Kriteriji za določitev optimalne razporeditve delovnih sredstev na primeru proizvodnega obrata Mizarstvo Jezeršek doo. Diss. Univerza v Mariboru, Fakulteta za organizacijske vede, 2016. |

|

Endüstriyel bir işletmede tesis yerleşim düzeni ve malzeme akış ağı tasarımının optimizasyonu |

Aslan, Fethi. "Endüstriyel bir işletmede tesis yerleşim düzeni ve malzeme akış ağı tasarımının optimizasyonu." (2016). |

|

A hybrid algorithm for optimising facility layout |

Tasadduq, I. A., M. H. Imam, and A. Ahmad. "A hybrid algorithm for optimising facility layout." South African Journal of Industrial Engineering 26.1 (2015): 120-134. |

|

Techniques for Solving Facility Layout Problem: A Survey |

Patil, Nitish D., V. A. Deshpande, and J. Gandhi. "Techniques for Solving Facility Layout Problem: A Survey." Afro-Asian International Conference on Science, Engineering & Technology AAICSET. 2015. |

|

A biased random-key genetic algorithm for the unequal area facility layout problem |

Gonçalves, José Fernando, and Mauricio GC Resende. "A biased random-key genetic algorithm for the unequal area facility layout problem." European Journal of Operational Research 246.1 (2015): 86-107. |

|

LEAN IMPLEMENTATION IN ELECTRICAL PANEL BOARD MANUFACTURING INDUSTRY |

Sivagurunathan, S., and D. Rajenthirakumar. "LEAN IMPLEMENTATION IN ELECTRICAL PANEL BOARD MANUFACTURING INDUSTRY." International Journal of Advances in Engineering & Technology 8.1 (2015): 1901. |

|

Optimisation of facility layout design problem with safety and environmental factors by stochastic DEA and simulation approach |

Azadeh, A., T. Nazari, and H. Charkhand. "Optimisation of facility layout design problem with safety and environmental factors by stochastic DEA and simulation approach." International Journal of Production Research 53.11 (2015): 3370-3389. |

|

İşyeri Düzenleme Algoritmalarının İncelenmesi ve Bir Fabrika Uygulaması |

Durak, İsmail, and Mehmet YILDIZ. "P-Medyan Tesis Yeri Seçim Problemi: Bir Uygulama." Uluslararası Alanya İşletme Fakültesi Dergisi 7.2 (2015). |

|

SIMULATION OPTIMIZATION OF FACILITY LAYOUT DESIGN PROBLEM WITH SAFETY AND ERGONOMICS FACTORS. |

Azadeh, Ali, and Bita Moradi. "SIMULATION OPTIMIZATION OF FACILITY LAYOUT DESIGN PROBLEM WITH SAFETY AND ERGONOMICS FACTORS." International Journal of Industrial Engineering 21.4 (2014). |

|

Redesigning of manufacturing layout for performance improvements using VIP plan opt software |

Vetrivel, R., V. Vasantha Kumar, and K. Thillaivadivazhagan. "Redesigning of manufacturing layout for performance improvements using VIP plan opt software." International Journal of Engineering, Science and Mathematics 2.3 (2013): 20-35. |

|

A two-step heuristic algorithm for layout design of unequal-sized facilities with input/output points |

Xiao, Yujie, Yoonho Seo, and Minseok Seo. "A two-step heuristic algorithm for layout design of unequal-sized facilities with input/output points." International Journal of Production Research 51.14 (2013): 4200-4222. |

|

Obtaining an initial solution for facility layout problem |

Shoja Sangchooli, Ali, and Mohammad Reza Akbari Jokar. "Obtaining an initial solution for facility layout problem." Journal of Industrial Mathematics 2013 (2013). |

|

New shipyard layout design for the preliminary phase & case study for the green field project |

Song, Young Joo, and Jong Hun Woo. "New shipyard layout design for the preliminary phase & case study for the green field project." International Journal of Naval Architecture and Ocean Engineering 5.1 (2013): 132-146. |

|

An Integrated Fuzzy Algorithm for Job Shop Layout Optimization: The Case of Maintenance Workshop Process |

Azadeh, A., and S. Jebreili. "An Integrated Fuzzy Algorithm for Job Shop Layout Optimization: The Case of Maintenance Workshop Process." 2nd International Conference on Mechanical, Automobile and Robotics Engineering. 2013. |

|

Implementing overall equipment effectiveness in a process industry |

Palanisamy, V., and Jose Ananth Vino. "Implementing overall equipment effectiveness in a process industry." Indian Journal of Science and Technology 6.6 (2013): 4789-4793. |

|

A NOVEL ADAPTIVE BOUNDARY SEARCH ALGORITHM FOR SOLVING FACILITY LAYOUT PROBLEMS1 |

Tasadduq, Imran A., M. H. Imam, and Abdul-Rahim Ahmad. "A novel adaptive boundary search algorithm for solving facility layout problems." (2013). |

|

Facility Layout |

Malakooti, Behnam. "Facility Layout." Operations and Production Systems with Multiple Objections, Wiley (2013). |

|

A multi-objective particle swarm optimisation algorithm for unequal sized dynamic facility layout problem with pickup/drop-off locations |

Jolai, Fariborz, Reza Tavakkoli-Moghaddam, and Mohammad Taghipour. "A multi-objective particle swarm optimisation algorithm for unequal sized dynamic facility layout problem with pickup/drop-off locations." International Journal of Production Research 50.15 (2012): 4279-4293. |

|

An artificial immune system based algorithm to solve unequal area facility layout problem |

Ulutas, Berna Haktanirlar, and Sadan Kulturel-Konak. "An artificial immune system based algorithm to solve unequal area facility layout problem." Expert Systems with Applications 39.5 (2012): 5384-5395. |

|

A novel metasearch algorithm for facility layout optimization |

Tasadduq, Imran A., M. H. Imam, and Abdul-Rahim Ahmad. "A novel metasearch algorithm for facility layout optimization." Proc. of 41st Intl. Conference on Computers and Industrial Engineering. 2011. |

|

Heuristics for the dynamic facility layout problem with unequal-area departments |

McKendall Jr, Alan R., and Artak Hakobyan. "Heuristics for the dynamic facility layout problem with unequal-area departments." European Journal of Operational Research 201.1 (2010): 171-182. |

|

Structural Optimization Using a Novel Genetic Algorithm for Rapid Convergence |

Al-Shihri, M. A. "Structural Optimization Using a Novel Genetic Algorithm for Rapid Convergence." International Journal of Civil & Structural Engineering 1.2 (2010): 123-138. |

|

Facility Network Optimization |

Zavari, Jouian. Facility Network Optimization. 2010. |

|

Design and optimization of manufacturing facilities layouts |

Balamurugan, K., V. Selladurai, and B. Ilamathi. "Design and optimization of manufacturing facilities layouts." Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture 220.8 (2006): 1249-1257. |

|

An efficient, effective, and robust decoding heuristic for metaheuristics-based layout optimization |

Ahmad, Abdul-Rahim, et al. "An efficient, effective, and robust decoding heuristic for metaheuristics-based layout optimization." International journal of production research 44.8 (2006): 1545-1567. |

|

An intelligent expert system for decision analysis and support in multi-attribute layout optimization |

Ahmad, Abdul-Rahim. "An intelligent expert system for decision analysis and support in multi-attribute layout optimization." (2005). |

|

Cascading flowlines and layout modules: Practical strategies for machine duplication in facility layouts |

Irani, Shahrukh A., and Heng Huang. "Cascading flowlines and layout modules: Practical strategies for machine duplication in facility layouts." International Journal of Flexible Manufacturing Systems 17 (2005): 119-149. |

|

A hierarchical placement strategy for generating superior layout decision alternatives |

Ahmad, A., et al. "A hierarchical placement strategy for generating superior layout decision alternatives." International Journal of Operations and Quantitative Management 11.4 (2005): 261. |

|

A Placement Algorithm for Efficient Generation of Superior Decision Alternatives in Layout design |

Ahmad, Abdul-Rahim, et al. "A Placement Algorithm for Efficient Generation of Superior Decision Alternatives in Layout design." Proc. of the 5th Int’l Conf. on Operations and Quantitative Management (ICOQM-V). 2004. |

|

Improved placement algorithm for layout optimization |

Ahmad, Abdul-Rahim, et al. "Improved placement algorithm for layout optimization." Proc. of the 2nd Int’l Industrial Engineering Conf.(IIEC’04). 2004. |